Want To Finally Understand Industrial Controls Troubleshooting?

If you’ve ever stared at a panel, felt lost, or wished someone would just show you how to troubleshoot step-by-step — you’re in the right place.

Fault Fixer Troubleshooting Course

Become the go-to troubleshooter in 90 days or less with our step-by-step, foundational troubleshooting training course.

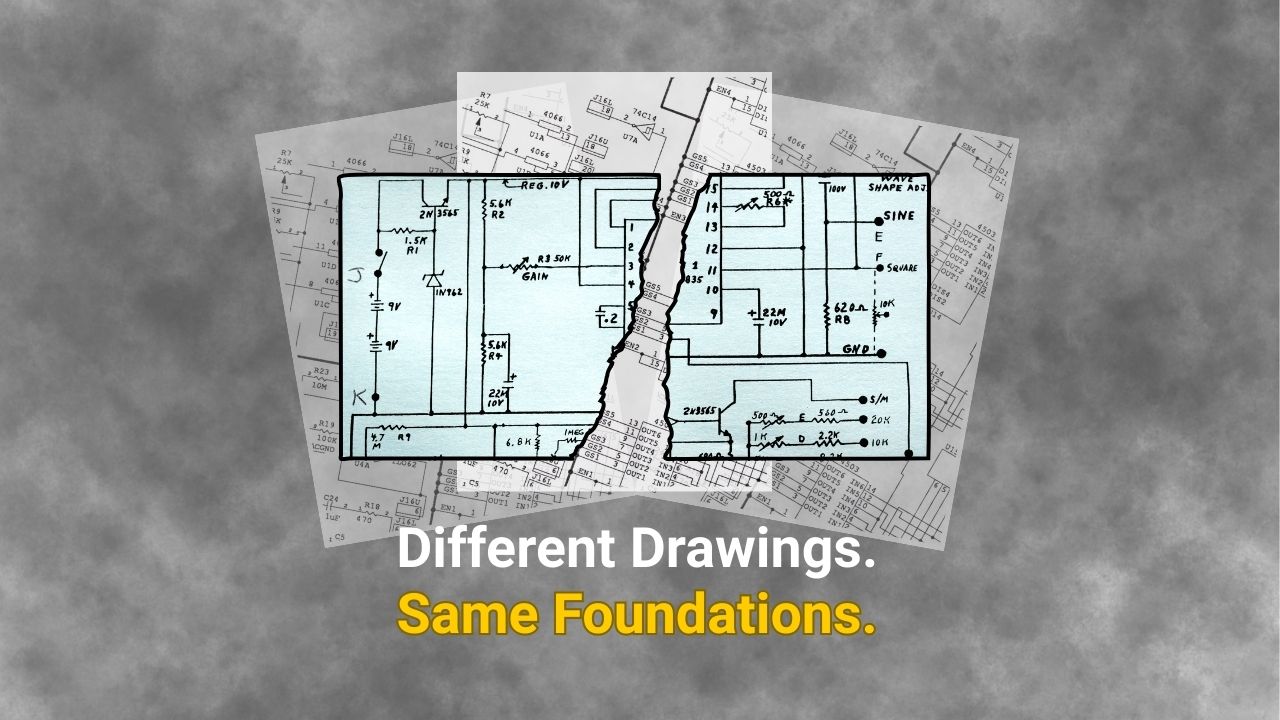

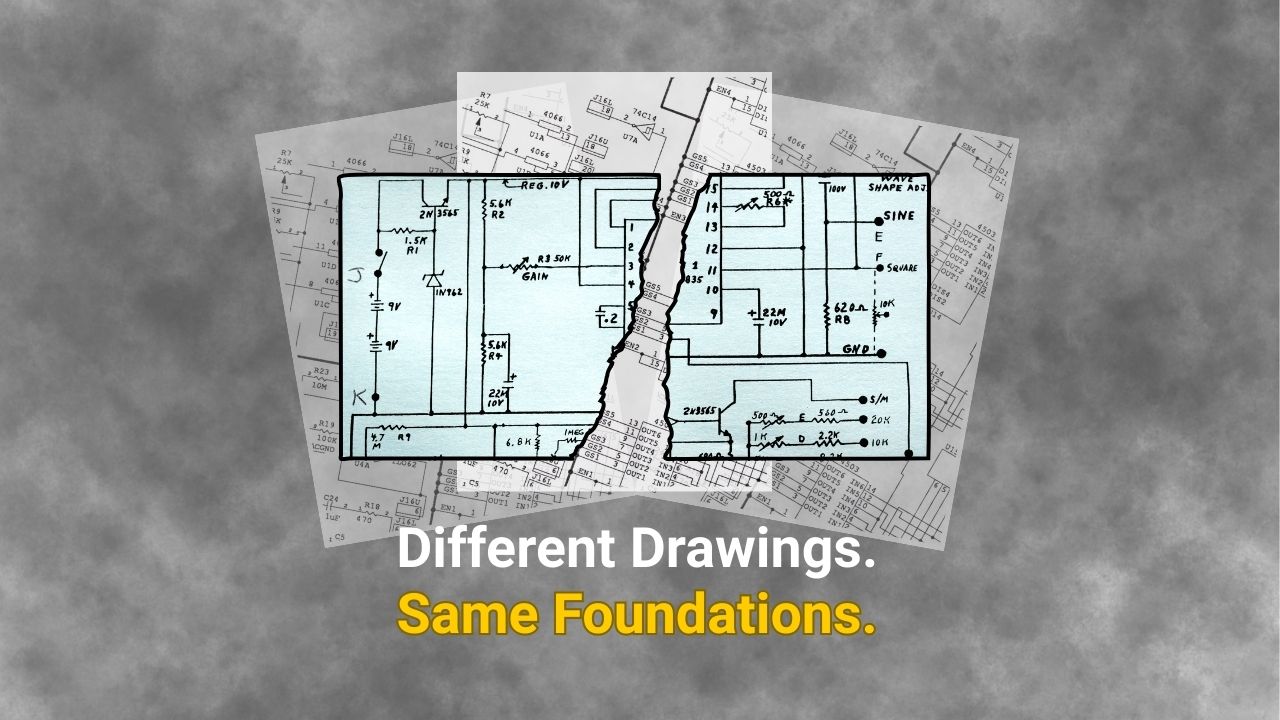

Decode Electrical Schematics

Blueprint Bootcamp: Learn to read schematics with clarity — not memorization.

Rapid Component Diagnostics

Cheat sheet testing guides for real electrical & pneumatic faults.

Fault Fixer Troubleshooting Course

Become the go-to troubleshooter in 90 days or less with our step-by-step, foundational troubleshooting training course.

Decode Electrical Schematics

Blueprint Bootcamp: Learn to read schematics with clarity — not memorization.

Rapid Component Diagnostics

Cheat sheet testing guides for real electrical & pneumatic faults.

MEET THE FOUNDEr

Hey, I'm Jordon!

I didn’t start out confident with controls. I struggled like everyone else — but I was fortunate enough to have a mentor who taught me the right way to troubleshoot.

That changed everything for me.

And I realized most techs never get that kind of guidance.

So I built this Fault Fixer Course to pass on what I was given — a practical, real-world troubleshooting system that helps new and developing technicians go from unsure to confident.

Over 300+ techs have used this approach to stop guessing, start understanding, and become the person others rely on when something breaks.

Developer of the Fault Fixer Troubleshooting Course.

Trained 160+ technicians to master troubleshooting.

Trusted by maintenance leaders across industries.

If you’ve ever opened a panel and felt lost, you’re exactly who I built this for.

MEET THE FOUNDEr

Hey, I'm Jordon!

I didn’t start out confident with controls. I struggled like everyone else — but I was fortunate enough to have a mentor who taught me the right way to troubleshoot.

That changed everything for me.

And I realized most techs never get that kind of guidance.

So I built this Fault Fixer Course to pass on what I was given — a practical, real-world troubleshooting system that helps new and developing technicians go from unsure to confident.

Over 300+ techs have used this approach to stop guessing, start understanding, and become the person others rely on when something breaks.

Developer of the Fault Fixer Troubleshooting Course.

Trained 160+ technicians to master troubleshooting.

Trusted by maintenance leaders across industries.

If you’ve ever opened a panel and felt lost, you’re exactly who I built this for.